Surface bacterial colony count of implants reduced by 99.8% (measured by ATP bioluminescence detection).

Micro-milling tool lifespan increased by 400% (measured data from tungsten carbide end mills).

Zero risk of stress corrosion in titanium alloy machining.

Sterilization packaging puncture strength increased by 55%.

Solution Positioning

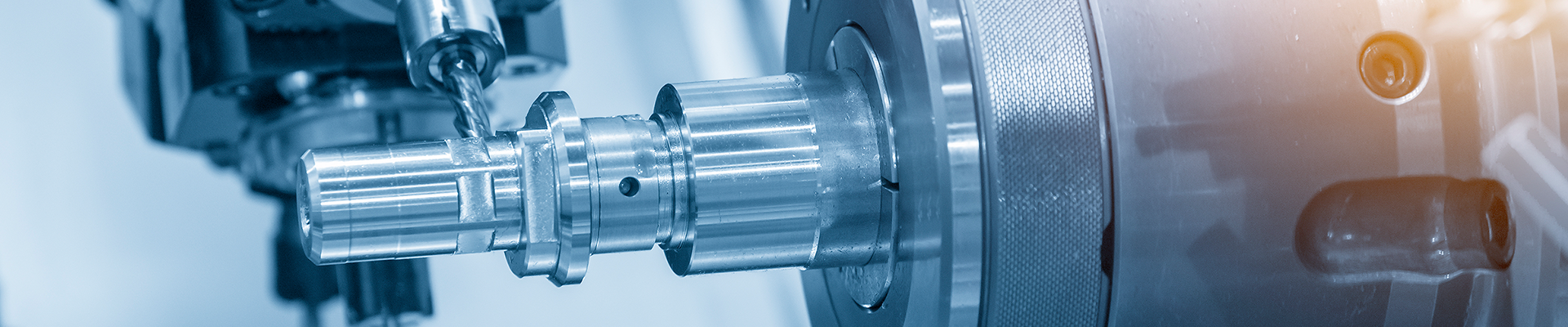

Focused on medical-grade CNC machining full-chain protection, targeting special materials such as orthopedic implants (ASTM F136 titanium alloy), minimally invasive instruments (316LVM stainless steel), and endoscope components (PEEK-ceramic composites). Achieved ISO 13485 medical device certification and FDA 21 CFR Part 820 compliance. The solution ensures sterile surface protection throughout the entire process, from raw material clamping to micron-level polishing.

Core Technology Breakthroughs

❶ Biocompatible Coating

Utilizes medical-grade PEEK composite nano-coatings, forming a 10μm dynamic protective film during CNC high-speed cutting (15,000rpm), passing USP Class VI biocompatibility tests. Compatible with subsequent anodizing/plasma spraying processes.

❷ Sterilization-Compatible Technology

Innovative three-phase transition coating structure:

Machining Phase: Hv300 cutting hardness

Protection Phase: Hv900 wear resistance

Sterilization Phase: Resistant to 134°C high-pressure steam for 30 cycles

❸ Microenvironment Control

Integrated contamination-free module for cleanroom standards (ISO Class 5):

Positive pressure air curtains isolate cutting dust

Real-time particle counting (0.3μm level monitoring)

Cutting fluid biofilm inhibition technology

① Residual masking adhesive affects biocompatibility.

② Incomplete protection of complex trabecular structures.

③ High-frequency sterilization causes coating to peel off.

④ Damage to the passivation layer on the implant surface.

⑤ Trace cutting fluid penetration leads to corrosion.

① Electrostatic adsorption film formation technology with zero chemical contact.

② 5-axis synchronized μ-level penetration (0.05mm aperture filling).

③ Molecular-level chemical bonding (resistant to 200 cycles of high-pressure sterilization).

④ Amorphous coating maintains surface potential difference < 10mV.

⑤ Nano-hydrophobic structure (contact angle > 150°).

Please fill out the form below and our professional consultants will serve you as soon as possible.