In today's precision manufacturing field, the importance of CNC machining is unquestionable. Our CNC Machining Surface Protection Technology Research Center, with its unique technological strength and innovative concepts, remains steadfastly focused on pioneering CNC protection technologies.

Top-Notch R&D Team

Our R&D team brings together elite talents from various fields, including materials science, mechanical engineering, and chemical processes. Materials science experts, with their in-depth understanding of material properties, continuously explore the application potential of new materials in CNC protection. The mechanical engineering core ensures that the protection solutions seamlessly integrate with CNC machining processes. Chemical process specialists focus on developing formulations for protective materials, optimizing their performance. Additionally, data analysts leverage deep insights from extensive experimental data to provide strong evidence for technical improvements.

Outstanding Technical Achievements

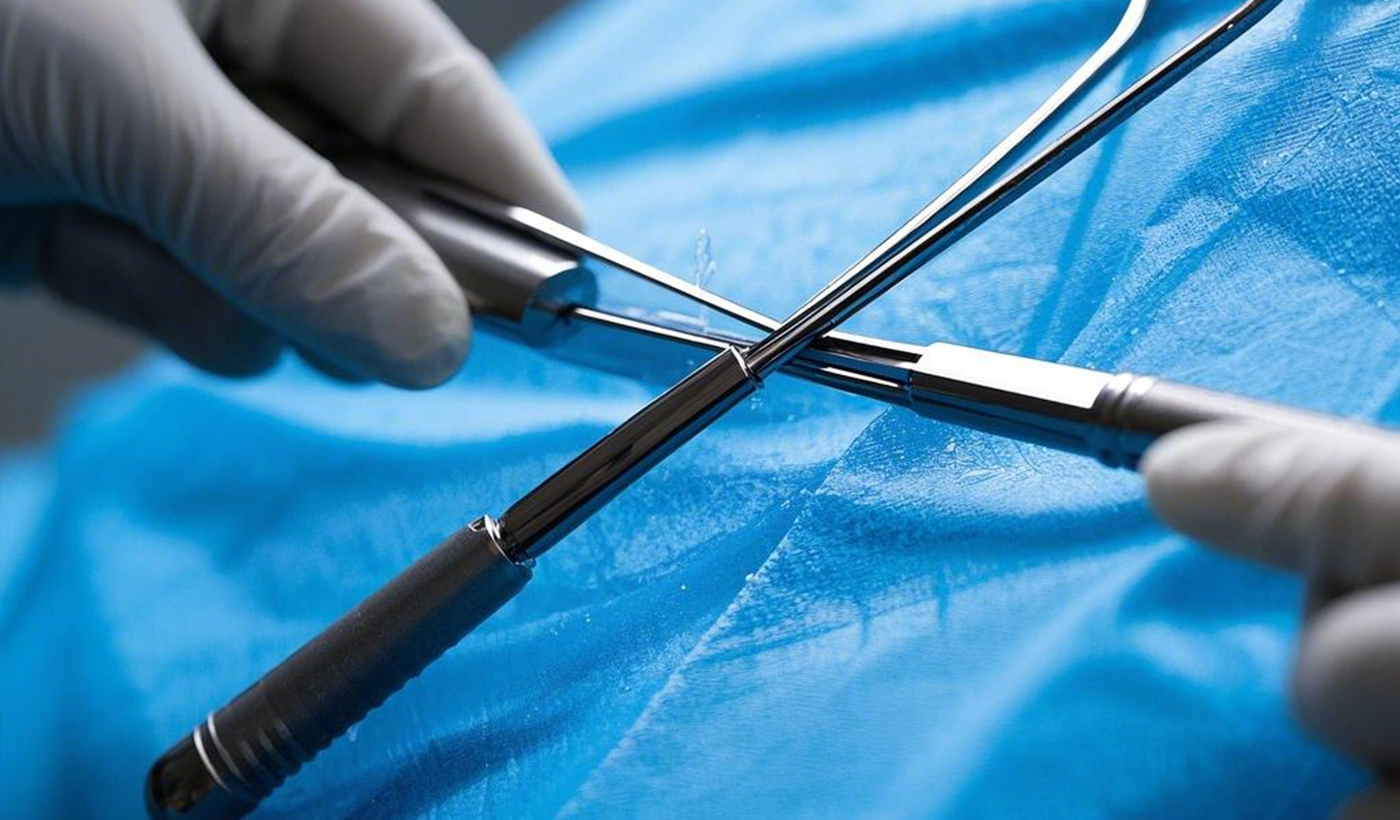

After countless experiments and the accumulation of vast amounts of data, we have successfully developed a series of protection solutions with exceptional performance. These solutions feature high precision, enabling them to perfectly conform to the surfaces of various complex CNC machined parts, providing comprehensive and meticulous protection. The low waste aspect is reflected in the efficient use of materials, significantly reducing production costs and aligning with the principles of green manufacturing. The high-temperature resistance is exceptional; even in extreme working environments, the protection remains stable, ensuring that the quality of the machined parts is not affected by high temperatures. Furthermore, the protective material is easy to remove; after processing, it can be effortlessly peeled off the part's surface without leaving any residue, facilitating subsequent processing steps.

Brilliant Success Stories

In practical applications, we have achieved numerous outstanding results. We partnered with Omron, a leading medical device company, to successfully overcome the challenge of surface biocompatibility for critical medical implant components in complex human physiological environments. After applying our proprietary surface treatment technology, the compatibility success rate between the components and human tissues increased from 70% to 90%, significantly reducing the risk of implant surgery failure and providing solid protection for patients' health and safety.

In the field of medical consumables manufacturing, we collaborated with several industry-leading companies to optimize the production processes of core components such as single-use syringes and infusion sets. By adopting our technology, production efficiency increased by 30%, while scrap rates were reduced by 50%. This not only effectively shortened production cycles but also lowered costs, allowing more patients to benefit from high-quality and reasonably priced medical consumables. It also significantly enhanced the companies' competitiveness in the market.

We deeply understand that technological innovation plays a crucial role in driving the development of the healthcare industry. Therefore, our research center actively engages in in-depth cooperation and communication with major medical institutions and medical research institutes. We are committed to applying our innovative technologies extensively across various medical material-related fields, such as medical implants, medical consumables, and diagnostic equipment. Through practical actions, we are pushing forward technological advancements within the healthcare industry, helping the medical precision manufacturing sector reach new heights of development.