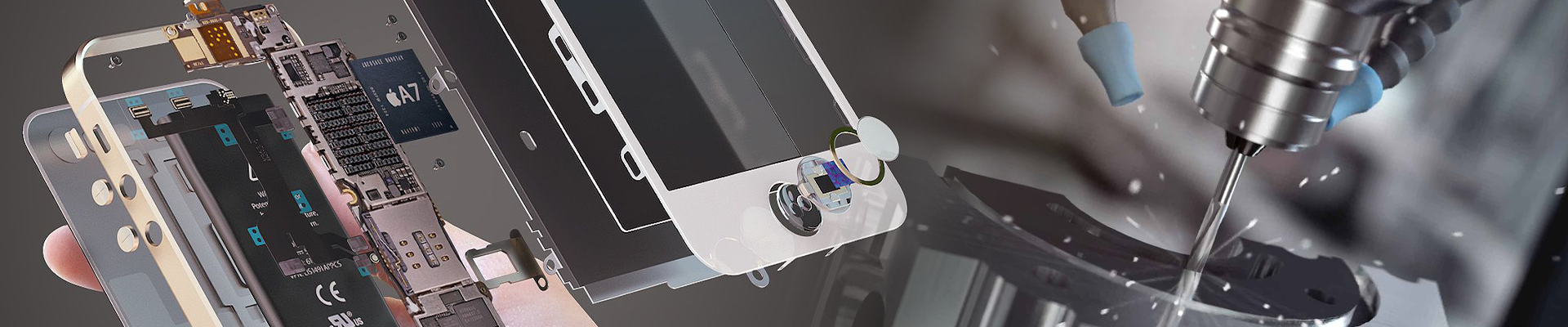

Innovative CNC Anodic Protection Solution Global Debut

— Smart Masking Technology Redefines Metal Surface Treatment Efficiency and Precision

Disruptive Intelligent Masking System

AI Vision Dynamic Positioning:

Equipped with a 10μm industrial camera and deep learning algorithms, the system accurately identifies CNC machining features (such as drilling and chamfering) within 0.5 seconds, automatically generating the optimal masking path. Boundary control precision reaches ±0.03mm.

Digital Inkjet Protective Layer:

The patented water-based coating (FDA-certified) is directly inkjet-printed, perfectly adhering to curved surfaces and complex structures, replacing traditional film application and improving efficiency by 800%.

Ultimate Anodizing Quality Assurance

Strong Acid Resistance Black Technology:

The coating is immersed in 15% sulfuric acid anodizing solution for 12 hours without penetration, effectively solving industry issues such as boundary seepage and color variation.

Thermal Deformation Compensation Technology:

Real-time monitoring of anodizing bath temperature (40-60°C), with the coating’s expansion coefficient automatically matching the base material, eliminating the risk of high-temperature delamination.

Green Manufacturing Ecosystem

Zero Chemical Stripping Revolution:

Ultrasonic pure water stripping (3 minutes per batch), with wastewater nano-filtered and 100% recycled, reducing environmental costs by 90% compared to solvent-based stripping.

Carbon Footprint Visualization:

Only 0.3kg of carbon emissions per 10,000 parts processed, certified by ISO 14067 international standards.

✅ Global Exclusive: The first-ever CNC-anodizing full-process intelligent protection integration machine.

✅ Peak Yield: Anodizing appearance defect rate reduced from 12% to 0.3%.

✅ Explosive Efficiency: Processes 25 parts per minute, with daily capacity exceeding 20,000 parts.

✅ Cost Revolution: Overall costs reduced by 55% compared to traditional solutions.

✅ Sustainability Certification: Complies with Apple MMI and Dell DSG dual green standards.

3C Electronics: Multi-color anodizing masking for mobile phone aluminum alloy frames.

Automotive Parts: Local anodizing hardening for magnesium alloy wheels.

Medical Devices: Biocompatible surface treatment for titanium alloy implants.

Drones: Conductive anodic protection for carbon fiber composite parts.

Foxconn Technology Group: Introduced into the iPhone 15 titanium alloy frame production line, improving yield to 99.7%.

Tesla Supply Chain: Applied to the Cybertruck stainless steel door trim anodizing, tripling production efficiency.

Johnson & Johnson Medical: Titanium alloy anodizing process for orthopedic instruments passed FDA GMP certification.

48-Hour Rapid Sampling: Free CNC sample protection testing.

IoT Remote Monitoring: Real-time equipment diagnostics, with a fault prediction accuracy rate of 99%.

Customized Development: Supports special materials (such as nickel-titanium alloys, silicon carbide) for formula adaptation.