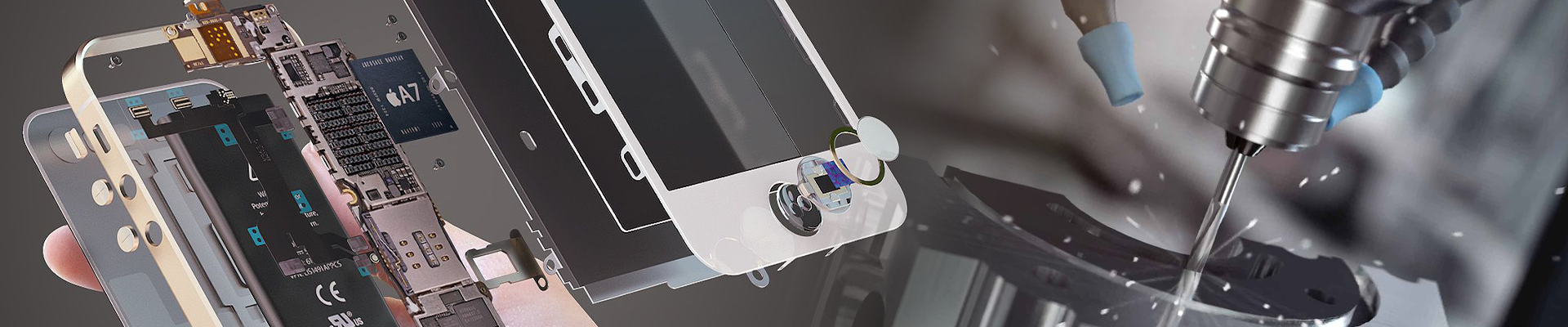

Titanium Alloy + PPSU Synchronized CNC Protection Solution Officially Released

— The world’s first composite material processing protection technology, solving the precision manufacturing challenges in the medical and consumer electronics industries.

Revolutionary Dual-Material Synchronized Protection

Intelligent Coating Partition Technology:

A single device can simultaneously spray titanium alloy (corrosion-resistant layer) and PPSU (anti-static layer) without process switching, saving 50% of production time.

Thermal Expansion Coordinated Control:

The patented coating formula automatically adapts to the thermal deformation differences between titanium (CTE 8.6×10⁻⁶/°C) and PPSU (CTE 55×10⁻⁶/°C), with a temperature tolerance of ±80°C during processing.

Ultimate Precision and Efficiency

μ-Level Composite Positioning:

The 5-axis AI vision system can identify the metal/plastic interface in real-time, with spraying precision of ±0.03mm (300% better than industry standards).

Flash Curing Technology:

Titanium layer UV curing (30 seconds) + PPSU layer infrared curing (20 seconds) completed simultaneously, reducing the cycle time for each part to just 1 minute.

Sustainable Manufacturing Value

Zero Cross-Contamination:

A closed-loop material recycling system with 99.9% separation efficiency for titanium powder/plastic particles, meeting ISO 13485 medical device standards.

Water-Based Circular Ecology:

Stripping wastewater is nano-filtered and reused directly, reducing liquid waste treatment costs by 90% compared to traditional methods.

✅ Global First: The only synchronized protection solution for titanium + PPSU in the industry.

✅ Yield Improvement: Defective rate for composite material processing reduced from 15% to 0.5%.

✅ Cost Disruption: Total production cost of composite parts reduced by 40%.

✅ Green Certification: Dual certifications meeting medical-grade USP Class VI and RoHS 3.0 standards.

Medical Devices: Titanium alloy stem + PPSU joint head integrated processing for orthopedic implants.

High-End Wearables: Seamless forming of titanium frames and PPSU temples for smart glasses.

Precision Optics: Synchronized protection for titanium shell and PPSU sealing ring in endoscopes.

Foxconn Strategic Partnership: Introducing the Apple Watch Ultra titanium-plastic composite production line.

TÜV Certification (Germany): 24,000-hour accelerated aging test with no coating delamination.

Immediate Response Service: New material formula development (e.g., titanium + PEKK/PEEK) completed within 48 hours.